Can Hydrogen Drive a Greener Steel Revolution?

Steel production is one of the biggest contributors to global CO2 emissions, accounting for around 8%. Heat treatment of steel is particularly problematic: the use of natural gas in this process generates up to 39 billion tons of CO2 each year.

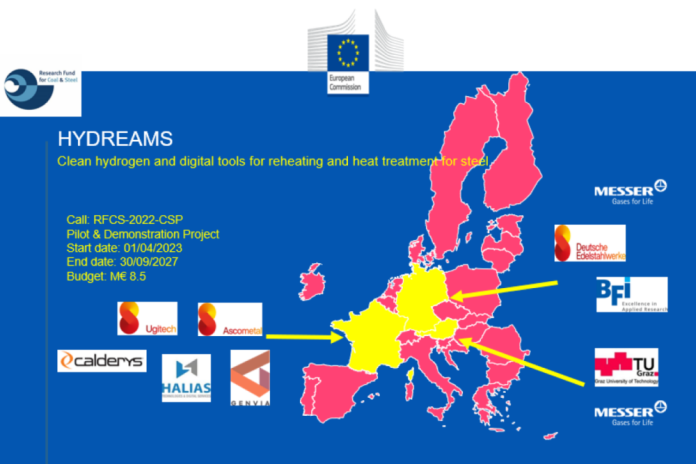

To tackle this issue, the Swiss Steel Group has been working since April 2023 on the EU-funded HYDREAMS project, which aims to replace natural gas with clean hydrogen. The project tests different furnace types (heating and annealing furnaces) as well as various burner systems (impulse and flame systems).

First Comprehensive Investigations

So far, there have been hardly any studies that examine in detail how hydrogen affects steel properties. Key factors include flame speed, radiation intensity, and the composition of exhaust gases.

“The replacement of natural gas with hydrogen in thermal processing is not yet mature and carries potential risks – including an increase in NOx emissions and possible negative impacts on steel quality as well as the lifetime of the refractory materials in the furnaces,” explains Laurent Sieye, Sustainability Manager Ugitech, Swiss Steel Group. “These are exactly the challenges the HYDREAMS project aims to research and find solutions for.”

From Laboratory Tests to Industrial Plants

The project is structured in several phases: from laboratory experiments and simulations to real industrial demonstrations. The first tests with 13 different steel grades already showed no structural or compositional differences in the samples.

Over the next few years, large-scale trials will be carried out. Three demonstration plants are planned – for blooms, forged ingots, and coils.

- DEMO 3: Operational since March 2025, first tests scheduled for summer 2025

- DEMO 1 & DEMO 2: Planned start in 2026

Contribution to EU Climate Goals

The initiative supports the EU’s climate objectives and could provide an attractive alternative to electric heating, which often comes with technical challenges such as uneven furnace temperatures or excessive wear of electrical resistances at high temperatures.

In addition to the technical aspects, the project will also deliver safety assessments, life cycle analyses, and cost evaluations. These findings will be crucial for a potential market launch.

https://www.wire-tradefair.com/

#GreenSteel#HydrogenEconomy#SteelInnovation#SustainableSteel#modernbusinessindia

#printpublication#printmagazine#modernbusinessworld